What is an Air Gap

In a commercial kitchen, clean water is your lifeline. But did you know that a simple drop in water pressure could turn your clean water supply into a toxic hazard?

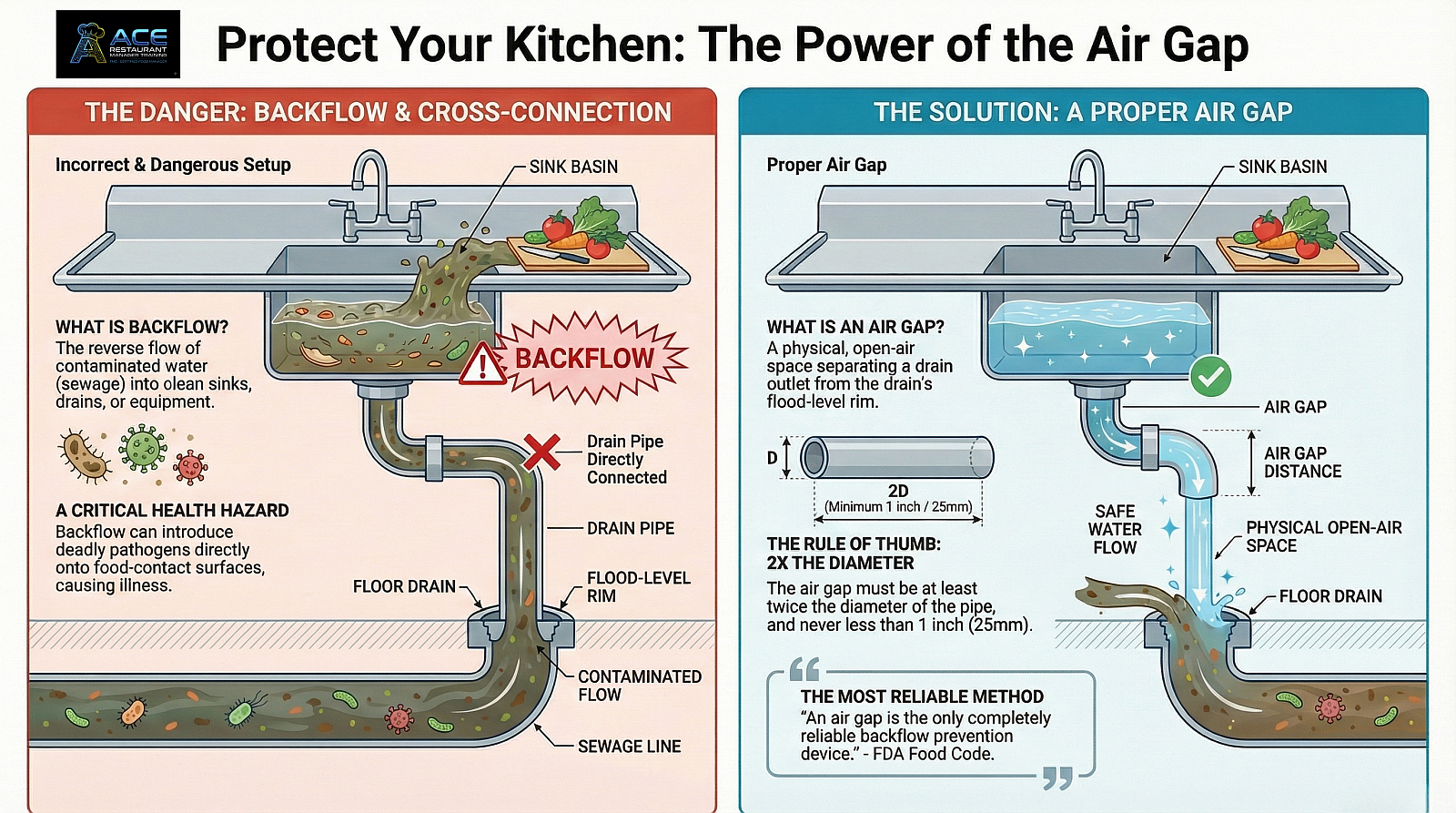

This phenomenon is called Backflow, and it is one of the most technical (and failed) sections of the Certified Food Protection Manager (CFPM) exam. While there are many devices designed to stop it—like vacuum breakers and double check valves—there is only one method that is universally accepted as fail-safe.

It is not a machine. It is physics. It is the Air Gap.

The Problem: Cross-Connections

The Problem: Cross-Connections

To understand the solution, you must understand the threat. A Cross-Connection is any physical link between safe, drinkable water and dirty water. What is an Air Gap

The most common example is a hose attached to a mop sink faucet that is left submerged in a bucket of dirty, soapy water.

If the building loses water pressure (due to a fire hydrant being used nearby or a main line break), a vacuum is created. This vacuum sucks the dirty mop water backwards through the hose and into your clean water pipes. This specific type of backflow is called Backsiphonage.

The Solution: The Air Gap

Mechanical backflow prevention devices rely on valves and springs. Eventually, valves get stuck and springs rust. They can fail.

An Air Gap is exactly what it sounds like: An open, vertical space between the water outlet (the faucet) and the flood level rim of the vessel (the sink).

Because dirty water cannot jump up through empty air to reach the faucet, an air gap is the only 100% reliable method to prevent backflow.

The Rule: 2x The Diameter

If you are studying for your ServSafe, FMC, or NRFSP exam, you must memorize the measurement rule for installing an air gap. What is an Air Gap

The Rule: The air gap must be at least twice the diameter of the water supply pipe.

-

Example: If your faucet pipe is 1 inch wide, your air gap must be at least 2 inches.

-

The Minimum: Regardless of pipe size, the air gap must never be less than 1 inch (25mm).

Common Air Gap Violations

Health Inspectors look for air gaps in two specific places. If you fail these, you will lose critical points.

1. Ice Machine Drain

Look under your ice machine. The drain pipe coming from the bin should not go directly into the floor drain. It should end above the floor drain, leaving a visible gap of air. If the sewer backs up, that air gap ensures sewage flows onto the floor, not into your ice.

2. 3-Compartment Sink

Similar to the ice machine, the drain lines from your wash, rinse, and sanitize sinks must terminate above the floor drain grate. If they are shoved down into the drain, you have a cross-connection.

Master the Plumbing Questions

Plumbing and water safety make up a significant portion of the Food Manager Exam. Don’t rely on guessing.

At ACE Restaurant Manager Training, we break down complex plumbing codes into simple, visual concepts during our live weekly webinars.

[> Click Here to View the Weekly Webinar Schedule & Register]

Frequently Asked Questions: Air Gaps

The only certain way to prevent backflow?

The only 100% reliable method to prevent backflow is an Air Gap. Unlike mechanical devices, an air gap uses physical separation that never fails.

How big must an air gap be?

An air gap must be at least twice the diameter of the water supply pipe, with a minimum distance of 1 inch (25mm).

What is a cross-connection?

A cross-connection is a physical link between safe water and dirty water, such as a hose submerged in a mop bucket or a drain line connected directly to a sewer.